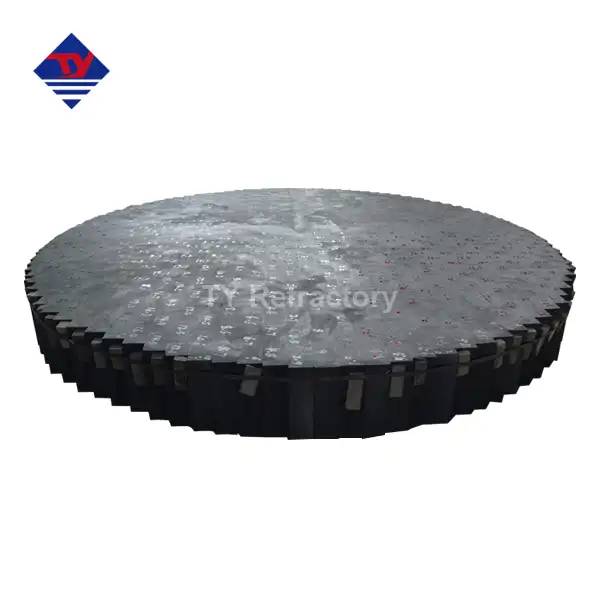

Composite Corundum Brick

Raw Material:corundum,silicon carbide,binder.

Advantages:Excellent high temperature performance, good shock resistance and wear resistance

Application:ceramic cup and ceramic pad of blast furnace

Providing customized services from product selection to project construction

TianYu Refractory Materials Co., LTD: Your Trusted Composite Corundum Brick Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we pride ourselves on delivering top-quality Composite Corundum Brick. With 38 years of industry expertise, ISO certifications, and 21 patents, we ensure superior products that meet your stringent requirements for high-temperature applications.

Introduction to Composite Corundum Brick

The products are essential components in various high-temperature industrial processes. These advanced refractory materials combine the exceptional properties of corundum (Al2O3) with carefully selected additives to enhance performance in extreme conditions. Our bricks offer outstanding resistance to thermal shock, corrosion, and wear, making them ideal for demanding applications in steelmaking, non-ferrous metallurgy, and other high-temperature industries.

About Our

MANAGEMENT SYSTEM CERTIFICATION

Key Attributes of Our Products

| Property | Value |

|---|---|

| Apparent Porosity (%) | ≤ 16 |

| Bulk Density(g/cm³) | 3.0-3.5 |

| Cold Crushing Strength (MPa) |

≥ 80 |

| Refractoriness | >1790 |

| Thermal Shock Resistance | Excellent |

| Chemical Composition | High alumina, corundum-based |

Product Features of Products

- Exceptional thermal stability

- High resistance to chemical corrosion

- Superior mechanical strength at elevated temperatures

- Low thermal conductivity

- Excellent wear resistance

Flow of Production

Raw Material Selection: High-purity alumina and corundum.

Mixing and Molding: Advanced processes ensure consistency.

High-Temperature Sintering: Achieves superior strength and stability.

Quality Inspection: Rigorous testing for dimensional accuracy and performance.

Packaging and Delivery: Secure and efficient logistics.

Applications of Products

- Steel industry: Blast furnaces, ladles, and torpedo cars

- Non-ferrous metallurgy: Smelting furnaces and reactors

- Cement production: Rotary kilns and preheaters

- Glass manufacturing: Melting tanks and regenerators

- Petrochemical industry: Process heaters and reformers

Why Choose TianYu for Your Product Needs?

- 38 years of refractory expertise

- ISO 9001:2015, ISO14001:2015, and OHSAS45001:2018 certified

- In-house R&D center and testing facilities

- Customizable solutions for your specific requirements

- Global supply capabilities with timely delivery

FAQ

Q: What is the minimum order quantity for products?

A: We offer flexible order quantities to meet your needs, from small batches to full container loads.

Q: Can you provide custom shapes and sizes?

A: Absolutely! We can manufacture products to your exact specifications.

Q: What is the typical lead time for bulk orders?

A: Lead times vary based on order size and specifications, but we strive for 4-6 weeks for standard products.

Q: Do you offer technical support for installation and maintenance?

A: Yes, our team of experts provides comprehensive technical support throughout the product lifecycle.

Q: Are your products compliant with international standards?

A: Our products meet and often exceed industry standards, including ASTM and ISO specifications.

Contact Us

Ready to enhance your high-temperature operations with our premium products? Contact our team at baiqiying@tianyunc.com for expert advice, custom quotations, and Composite Corundum Brick to discuss how we can meet your specific refractory needs.