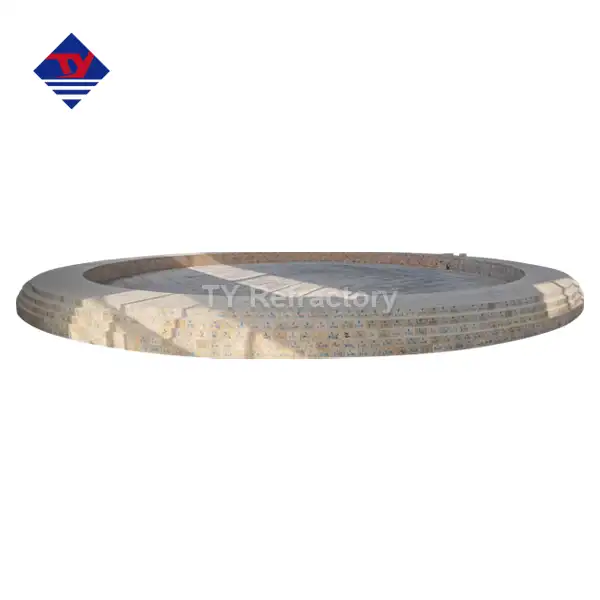

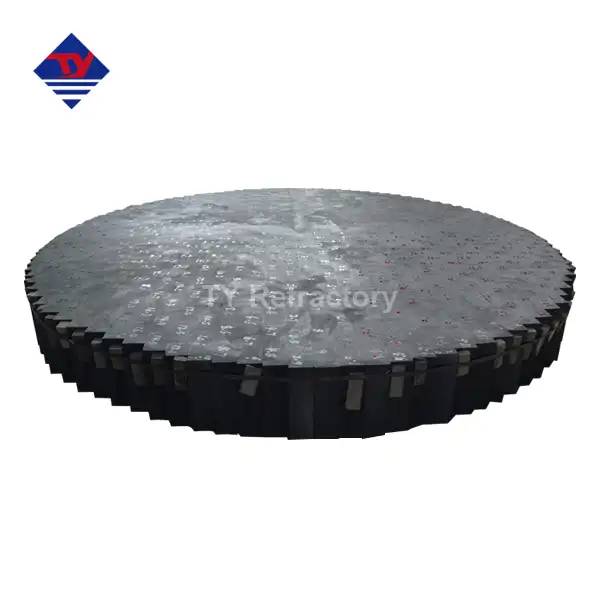

Compound Corundum Brick

Raw Material:corundum,silicon carbide,binder.

Advantages:Excellent high temperature performance, good shock resistance and wear resistance

Application:ceramic cup and ceramic pad of blast furnace

Providing customized services from product selection to project construction

TianYu Refractory Materials Co., LTD: Your Trusted Compound Corundum Brick Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we pride ourselves on delivering top-quality Compound Corundum Brick that exceed industry standards. With 38 years of expertise, our advanced production facilities and rigorous quality control ensure superior performance and longevity for your high-temperature applications.

Introduction to Products

The products are essential refractory materials designed for extreme environments. These high-alumina bricks combine exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for various industrial applications. Our products are engineered to withstand the harshest conditions in steel mills, non-ferrous metal smelting plants, and other high-temperature processes.

Key Attributes

| Property | Value |

|---|---|

| Alumina Content | >75% |

| Bulk Density | 3.0-3.2 g/cm³ |

| Cold Crushing Strength | >100 MPa |

| Refractoriness Under Load (T0.5) | >1700°C |

| Thermal Shock Resistance | >30 cycles |

Product Features

- Superior thermal stability for prolonged service life

- Excellent resistance to chemical corrosion and slag penetration

- High mechanical strength, even at elevated temperatures

- Low thermal expansion for improved structural integrity

- Customizable compositions to meet specific application requirements

Production Process

Our state-of-the-art manufacturing process ensures consistent quality:

- Raw material selection and preparation

- Precise mixing and forming

- Controlled drying and firing

- Rigorous quality testing and inspection

- Packaging and shipping

Applications

Compound Corundum Brick is widely used in:

- Steel industry: Blast furnaces, ladles, and torpedo cars

- Non-ferrous metal smelting: Furnace linings and transfer ladles

- Glass manufacturing: Melting furnaces and regenerators

- Cement production: Rotary kilns and preheater towers

- Petrochemical industry: Reactor linings and process vessels

Why Choose Us?

- 38 years of industry experience

- ISO 9001:2015, ISO 14001:2015, and OHSAS 45001:2018 certified

- 21 patents related to refractory products and processes

- In-house R&D center and testing facilities

- Customized solutions to meet your specific needs

FAQ

Q: What is the minimum order quantity for products?

A: We offer flexible order quantities to accommodate your needs. Please contact us for details.

Q: Can you provide technical support for installation?

A: Yes, our team of experts offers comprehensive technical support, including installation guidance and troubleshooting.

Q: How long is the typical lead time for bulk orders?

A: Lead times vary based on order size and specifications. We strive to meet your timeline and can discuss specific requirements.

Q: Do you offer samples for testing?

A: Certainly! We provide samples for quality assessment and compatibility testing.

Q: What certifications do your products have?

A: Our products meet international standards and are backed by ISO certifications. We can provide detailed specifications upon request.

Contact Us

Ready to elevate your refractory performance with our products? Contact our team at baiqiying@tianyunc.com for expert advice, custom quotations, and Compound Corundum Brick to discuss how we can support your specific industrial needs.