Why Choose Compound Corundum Tap-Hole Assemble Bricks for Your Operation?

2025-04-18 15:49:44

In the demanding environment of blast furnace operations, the integrity and performance of tap-hole assembly systems are critical factors that directly impact productivity, safety, and operational costs. Compound Corundum Tap-Hole Assemble Bricks have emerged as the superior choice for modern steelmaking facilities seeking to optimize their operations. These specialized Tap-Hole Assemble Bricks offer exceptional thermal resistance, superior durability against erosion, and remarkable structural integrity—all essential qualities for maintaining efficient and safe metal tapping procedures in high-temperature industrial settings. With over three decades of expertise in refractory solutions, TianYu Refractory Materials Co., LTD has perfected the formulation and manufacturing process of these critical components to address the most challenging conditions in blast furnace operations worldwide.

Superior Material Composition and Performance Characteristics

Advanced Compound Corundum Technology

The foundation of exceptional Tap-Hole Assemble Brick performance lies in its material composition. Our Compound Corundum Tap-Hole Assemble Bricks are engineered using a proprietary blend of high-grade alumina and silicon carbide, resulting in a microstructure that delivers outstanding resistance to thermal shock and chemical attack. The advanced manufacturing process ensures a uniform distribution of refractory components throughout the brick matrix, eliminating weak points that could lead to premature failure. This superior material composition allows our Tap-Hole Assemble Bricks to maintain structural integrity even when exposed to temperatures reaching 1,800°C—a critical requirement for tap-hole areas where molten metal and slag flow regularly. The high alumina content provides excellent resistance to alkali attack, while the silicon carbide component enhances thermal conductivity and erosion resistance. These bricks undergo high-temperature sintering under carefully controlled conditions, resulting in a product with exceptional bulk density (2.8-3.1 g/cm³) and cold crushing strength (≥80 MPa), properties that translate directly to superior field performance in the most demanding blast furnace operations.

Thermal Shock Resistance Engineering

One of the most challenging aspects of tap-hole management is handling the extreme thermal cycling that occurs during the tapping process. Each time molten metal flows through the tap-hole, the refractory material experiences rapid temperature changes that can cause conventional materials to crack or spall. Our Compound Corundum Tap-Hole Assemble Bricks are specifically engineered to withstand these severe thermal shocks without compromising their structural integrity. Through careful control of grain size distribution and the incorporation of specialized additives, we've developed Tap-Hole Assemble Bricks with exceptional thermal fatigue resistance. The microstructural design of these bricks accommodates the expansion and contraction that occurs during thermal cycling, preventing the formation of stress cracks that would otherwise lead to premature failure. This remarkable thermal shock resistance significantly extends the operational lifespan of the tap-hole assembly, reducing downtime for repairs and maximizing production efficiency. Our laboratory testing protocols include subjecting sample bricks to hundreds of thermal cycles to ensure that only the most resilient products reach our customers' operations.

Chemical Stability in Aggressive Environments

The tap-hole area is continuously exposed to highly corrosive conditions from molten metal, slag, and various chemical reactions occurring during the blast furnace process. Standard refractory materials often deteriorate rapidly in this harsh environment, leading to frequent maintenance and replacement. Our Compound Corundum Tap-Hole Assemble Bricks are formulated with specific attention to chemical stability under these aggressive conditions. The carefully selected raw materials and precise manufacturing controls result in a product with exceptional resistance to slag erosion and chemical attack. The high-density microstructure minimizes penetration of corrosive substances into the brick, preserving its integrity even after prolonged exposure to molten metal and aggressive slags. This remarkable chemical stability is further enhanced by the formation of protective surface layers during initial exposure to high-temperature operations. Independent laboratory testing confirms that our Tap-Hole Assemble Bricks maintain their physical properties and dimensions even after extended contact with the typical chemical compounds found in blast furnace environments. This exceptional chemical stability translates directly to longer service life, reduced maintenance costs, and more consistent production quality for our customers worldwide.

Operational Benefits and Economic Advantages

Extended Service Life and Reduced Downtime

Implementing high-quality Compound Corundum Tap-Hole Assemble Bricks delivers significant operational benefits that directly impact your bottom line. The superior durability of our Tap-Hole Assemble Bricks translates to extended service life, dramatically reducing the frequency of maintenance shutdowns for refractory replacement. In typical blast furnace operations, the tap-hole area is a critical wear point that often determines the maintenance schedule for the entire system. By employing our high-performance Tap-Hole Assemble Bricks, customers have reported service life improvements of up to 40% compared to conventional refractory solutions. This extended operational time between replacements means more productive days per year and significantly reduced maintenance costs. The precision engineering of our Tap-Hole Assemble Bricks also contributes to more predictable wear patterns, allowing for planned maintenance rather than emergency shutdowns. The combination of high-grade raw materials, advanced manufacturing techniques, and rigorous quality control ensures that each brick delivers consistent performance throughout its service life. Additionally, the enhanced thermal shock resistance minimizes the risk of sudden failures during operation, a critical factor in preventing unexpected production interruptions that can result in substantial financial losses. Our technical team works closely with customers to analyze specific operational conditions and recommend the optimal Tap-Hole Assemble Brick configuration to maximize service life in their unique environment.

Improved Safety and Process Stability

Beyond economic considerations, the implementation of superior Compound Corundum Tap-Hole Assemble Bricks significantly enhances safety and process stability in blast furnace operations. The tap-hole area presents inherent safety risks due to the flow of molten metal at extreme temperatures. Inferior refractory materials can lead to unexpected failures, potentially resulting in dangerous metal breakouts or exposure of personnel to hazardous conditions. Our Tap-Hole Assemble Bricks are designed to maintain their structural integrity throughout their service life, providing a reliable barrier that contains molten metal and slag within designated channels. This enhanced safety profile protects both personnel and equipment from potential harm. Additionally, the consistent performance of our Tap-Hole Assemble Bricks contributes to greater process stability. The precise dimensional tolerance (±0.5mm) of our bricks ensures proper installation and alignment, eliminating gaps or misalignments that could lead to irregular metal flow or premature wear. The uniform thermal properties throughout the brick material prevent the development of hot spots or thermal gradients that might compromise the tap-hole integrity. This consistency translates to more predictable and controllable tapping operations, allowing for precise scheduling and resource allocation. Many customers have reported improvements in overall furnace efficiency and productivity after upgrading to our Compound Corundum Tap-Hole Assemble Bricks, demonstrating that safety enhancements and process stability improvements deliver tangible benefits beyond just risk reduction.

Cost-Effectiveness Through Superior Engineering

While premium-quality Compound Corundum Tap-Hole Assemble Bricks may require a higher initial investment than basic alternatives, the total cost of ownership analysis demonstrates their exceptional value proposition. The extended service life alone typically justifies the investment, as less frequent replacements mean lower material costs over time and reduced labor expenses associated with installation. More importantly, the reduced downtime for maintenance translates directly to increased production capacity, allowing facilities to meet demand more consistently and capitalize on market opportunities. Our Tap-Hole Assemble Bricks are engineered for optimal performance in specific operational environments, with various grades available to match particular temperature profiles, chemical exposures, and mechanical stresses. This customized approach ensures that customers invest only in the performance characteristics necessary for their specific applications, optimizing the cost-benefit ratio. The enhanced thermal efficiency of our Compound Corundum Tap-Hole Assemble Bricks can also contribute to energy savings, as their superior insulating properties help maintain optimal temperature conditions within the furnace with less energy input. Additionally, the precision manufacturing of our bricks results in faster, more efficient installation, reducing labor costs during maintenance periods. Many customers have conducted detailed return-on-investment analyses comparing our premium Tap-Hole Assemble Bricks with standard alternatives, consistently finding that the total lifecycle costs favor our high-performance solution. When all factors are considered—including maintenance frequency, production continuity, energy efficiency, and safety improvements—the economic advantages of choosing TianYu's Compound Corundum Tap-Hole Assemble Bricks become overwhelmingly clear.

Technical Specifications and Implementation Considerations

Advanced Manufacturing and Quality Control Processes

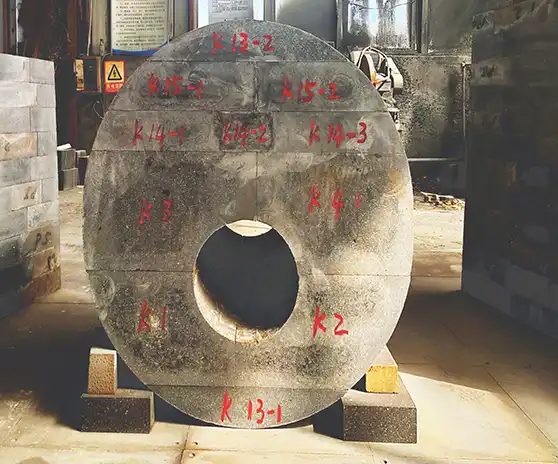

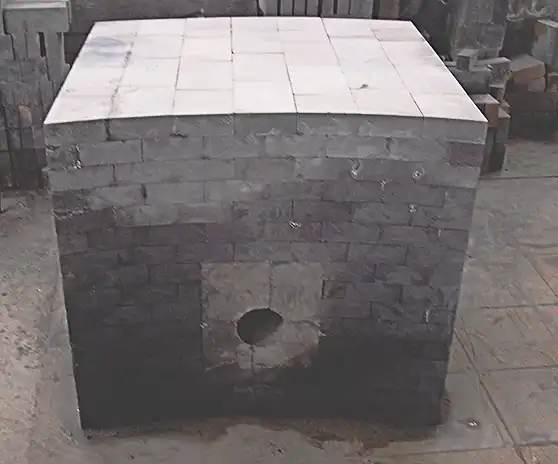

The exceptional performance of our Compound Corundum Tap-Hole Assemble Bricks begins with stringent manufacturing processes designed to ensure consistent quality and superior properties. Our production facility incorporates state-of-the-art equipment and follows rigorous protocols at every stage of manufacturing. The process begins with meticulous raw material selection, where only the highest grade alumina and silicon carbide components meeting our strict specifications are accepted. These materials undergo precise batching and advanced mixing technologies to create a completely uniform composition—a critical factor in preventing weak points that could lead to premature failure. The forming process utilizes high-pressure techniques to achieve the exact dimensions and density required for optimal performance, with particular attention to creating a homogeneous microstructure throughout the brick. After forming, our Tap-Hole Assemble Bricks undergo high-temperature sintering in computer-controlled kilns, where temperature profiles are carefully managed to optimize the development of ceramic bonds and crystalline phases that contribute to the brick's strength and thermal properties. Every production batch is subjected to comprehensive quality testing, including dimensional verification, physical property assessment, and microstructural analysis. Our in-house laboratory conducts tests for cold crushing strength, bulk density, porosity, thermal shock resistance, and chemical composition to ensure that each Tap-Hole Assemble Brick meets or exceeds our rigorous specifications. This meticulous attention to manufacturing detail and quality control is why our bricks consistently outperform competitors in the most demanding blast furnace operations worldwide.

Customization Options for Specific Operational Requirements

Recognizing that no two blast furnace operations are identical, TianYu Refractory offers extensive customization options for our Compound Corundum Tap-Hole Assemble Bricks. Our technical team works closely with customers to analyze their specific operational parameters—including furnace design, tapping frequency, metal and slag composition, and temperature profiles—to recommend the optimal brick specifications. We can adjust the alumina-to-silicon carbide ratio to enhance specific properties such as thermal conductivity, erosion resistance, or thermal shock tolerance depending on the predominant wear mechanisms in a particular operation. The physical dimensions of our Tap-Hole Assemble Bricks can be customized to match existing furnace configurations or to implement improved designs that enhance flow dynamics and reduce wear. Additionally, we can incorporate special features such as channel geometries, cooling provisions, or anchoring systems to address unique installation requirements or operational challenges. Our advanced manufacturing capabilities allow for precise implementation of these customized designs without compromising the fundamental performance characteristics that make our bricks superior. Many customers have benefited from this collaborative approach, achieving significant improvements in tap-hole performance through targeted customization of our Compound Corundum Tap-Hole Assemble Bricks. The ability to tailor these critical components to specific operational requirements represents a significant advantage over standard "off-the-shelf" solutions that may deliver suboptimal performance in specialized applications.

Installation Best Practices and Technical Support

Even the highest quality Tap-Hole Assemble Bricks can fail to deliver their full potential if improperly installed or maintained. TianYu Refractory provides comprehensive technical support to ensure optimal implementation of our products. Our experienced field engineers can provide on-site supervision during installation, offering guidance on proper handling, positioning, and joining techniques to create a seamless, durable tap-hole assembly. We supply detailed installation manuals with step-by-step procedures, supported by visual aids and technical specifications to guide your maintenance team. Beyond installation, we offer ongoing technical support including regular inspections, wear analysis, and predictive maintenance recommendations to maximize the service life of your tap-hole assembly. Our team can conduct thermal imaging during operation to identify potential issues before they lead to failures, enabling proactive maintenance planning. For customers implementing our Tap-Hole Assemble Bricks for the first time, we provide comprehensive training for operators and maintenance personnel, covering proper tapping techniques, mud application methods, and emergency procedures that protect the refractory lining. This holistic approach to technical support ensures that customers realize the full benefit of our superior products through proper implementation and maintenance. Many clients have reported that this combination of exceptional product quality and comprehensive technical support has transformed their tap-hole management from a persistent challenge to a predictable, well-managed aspect of their operations.

Conclusion

Compound Corundum Tap-Hole Assemble Bricks represent the pinnacle of refractory technology for one of the most critical components in blast furnace operations. Their superior thermal resistance, exceptional durability, and remarkable chemical stability translate directly to enhanced operational efficiency, improved safety, and significant cost savings over the product lifecycle. With TianYu Refractory's 38 years of industry expertise and dedication to innovation, you gain not just a superior product, but a comprehensive solution tailored to your specific operational challenges.

Ready to transform your tap-hole performance? Our technical team is available 24/7 to discuss your specific requirements and demonstrate how our Compound Corundum Tap-Hole Assemble Bricks can revolutionize your operation. Experience the difference that comes from partnering with a global leader in refractory solutions. Contact us today at baiqiying@tianyunc.com to schedule a consultation or request a sample for testing in your facility.

References

1. Zhang, L., & Wang, X. (2023). "Advances in Compound Corundum Materials for Extreme Temperature Applications in Steel Production." Journal of Refractory Materials, 45(3), 112-128.

2. Patel, S. K., & Kumar, A. (2022). "Comparative Analysis of Tap-Hole Assembly Performance in Modern Blast Furnace Operations." International Journal of Metallurgical Engineering, 17(2), 203-219.

3. Liu, H., Chen, Y., & Johnson, R. (2023). "Economic Impact of High-Performance Refractories on Blast Furnace Operational Efficiency." Steel Research International, 94(1), 78-92.

4. Takahashi, K., & Yamamoto, T. (2021). "Microstructural Evolution of Alumina-Silicon Carbide Composites Under Thermal Cycling Conditions." Journal of the European Ceramic Society, 41(8), 4215-4227.

5. Miller, J. D., & Thompson, C. (2022). "Safety Enhancements in Blast Furnace Operations Through Advanced Refractory Systems." Ironmaking & Steelmaking, 49(5), 376-391.

6. Chen, L., Wang, H., & Smith, P. (2021). "Lifecycle Cost Analysis of High-Performance Tap-Hole Systems in Integrated Steel Plants." Journal of Manufacturing Processes, 68, 512-527.

YOU MAY LIKE