What materials are used in the manufacturing of Fired Micro Hole ASC Bricks?

2025-04-29 14:44:09

Fired Micro Hole ASC Bricks are sophisticated refractory products engineered from a precise combination of premium raw materials designed to withstand extreme temperatures and harsh industrial environments. These specialized bricks utilize dense corundum, supergrade bauxite clinker, high-temperature electric calcined anthracite, graphite, and silicon carbide as their primary components. This strategic material composition gives Fired Micro Hole ASC Brick its exceptional properties - superior slag resistance, excellent thermal conductivity, and remarkable structural integrity that effectively protects cooling walls in blast furnaces. With an alumina (Al₂O₃) content exceeding 75%, these bricks provide the thermal stability and chemical resistance essential for critical applications in the steel industry, particularly in blast furnace belly, furnace waist, and lower furnace lining installations where maximum durability and performance are non-negotiable.

Core Materials and Their Contributions to ASC Brick Performance

Dense Corundum: The Foundation of Heat Resistance

Dense corundum serves as a crucial component in Fired Micro Hole ASC Brick manufacturing, providing the foundation for their exceptional heat resistance capabilities. This material, primarily composed of aluminum oxide (Al₂O₃), contributes significantly to the brick's ability to withstand temperatures exceeding 1750°C without deterioration. The crystalline structure of dense corundum creates a stable matrix that maintains dimensional stability even under extreme thermal conditions. When incorporated into Fired Micro Hole ASC Brick formulations, dense corundum enhances the overall refractory performance by increasing both thermal shock resistance and load-bearing capacity. TianYu Refractory Materials Co., LTD meticulously selects premium-grade dense corundum with precisely controlled particle size distribution to optimize the microstructure of the final product. This attention to detail in raw material selection contributes to the brick's impressive cold crushing strength of ≥80 MPa, making these refractory products ideal for high-stress applications in blast furnaces where both thermal and mechanical stresses are constant challenges. The corundum content also plays a vital role in maintaining the brick's integrity when exposed to molten metal and slag, protecting the critical cooling systems that prevent blast furnace shell overheating.

Supergrade Bauxite Clinker: Enhancing Structural Integrity

Supergrade bauxite clinker represents another essential material in the manufacturing of Fired Micro Hole ASC Brick, contributing substantially to the product's structural integrity and longevity. This premium raw material undergoes rigorous processing at TianYu Refractory's state-of-the-art facilities, where it is carefully calcined to achieve optimal mineralogical composition before incorporation into the brick formulation. The inclusion of supergrade bauxite clinker enhances the brick's apparent porosity, maintaining it at approximately 16% - a carefully calibrated level that balances mechanical strength with necessary thermal insulation properties. This controlled porosity is critical for the Fired Micro Hole ASC Brick's performance in blast furnace applications, where excessive porosity would compromise strength while insufficient porosity would reduce thermal shock resistance. The bauxite clinker also contributes to the brick's bulk density of 2.6 g/cm³, providing sufficient mass to resist displacement while maintaining manageable weight for installation. TianYu Refractory Materials Co., LTD sources only the highest quality bauxite clinker with low impurity content, particularly minimizing iron oxide and alkali metal contaminants that could compromise performance at high temperatures. This material selection strategy ensures that when installed in critical areas like furnace waists and lower linings, the Fired Micro Hole ASC Brick delivers consistent performance and predictable service life, even under the most demanding industrial conditions.

High-Temperature Electric Calcined Anthracite and Graphite: Carbon Sources for Enhanced Properties

High-temperature electric calcined anthracite and graphite constitute the critical carbon sources in Fired Micro Hole ASC Brick formulations, imparting several essential performance characteristics that distinguish these products in the marketplace. The inclusion of these carefully processed carbon materials significantly enhances the brick's thermal conductivity, allowing for more efficient heat transfer through the refractory lining. This property is particularly valuable in blast furnace applications where effective temperature management is essential for process efficiency and equipment longevity. TianYu Refractory Materials Co., LTD employs proprietary processing techniques to prepare these carbon sources, ensuring consistent quality and performance in every batch of Fired Micro Hole ASC Brick produced. The electric calcination process removes volatiles and impurities from the anthracite, creating a stable carbon source that resists oxidation even at extreme temperatures. When combined with high-purity graphite in precisely controlled proportions, these materials create a carbon network throughout the brick that dramatically improves resistance to molten slag penetration - a common failure mechanism in lesser refractory products. Additionally, the carbon content contributes to the impressive thermal shock resistance of ≥20 cycles at 1100°C, preventing catastrophic cracking during rapid temperature fluctuations that frequently occur during blast furnace operations. This remarkable thermal shock resistance extends the service life of the Fired Micro Hole ASC Brick, reducing downtime and replacement costs for steel producers worldwide who rely on TianYu's refractory solutions for their most demanding applications.

Manufacturing Process and Quality Control Measures

Raw Material Selection and Preparation Techniques

The manufacturing excellence of Fired Micro Hole ASC Brick begins with TianYu Refractory's meticulous raw material selection and preparation processes. Our technical experts implement a comprehensive multi-stage quality assurance protocol that examines every incoming batch of raw materials against stringent specifications. Dense corundum, supergrade bauxite clinker, high-temperature electric calcined anthracite, graphite, and silicon carbide undergo thorough chemical analysis and physical property testing before acceptance into our production stream. This rigorous screening ensures only premium-grade materials meeting our exacting standards are incorporated into Fired Micro Hole ASC Brick formulations. Our proprietary preparation techniques involve precise particle sizing through advanced grinding and classification systems, creating carefully controlled granulometric distributions that optimize the brick's microstructure. Each material component undergoes specific conditioning treatments to enhance compatibility and reactivity during the subsequent manufacturing stages. For high-temperature applications in blast furnaces, the quality of these raw materials directly impacts performance longevity, making this initial selection process critical to the final product's success. TianYu Refractory Materials Co., LTD maintains long-term partnerships with select suppliers who consistently deliver materials meeting our specifications, while our in-house testing laboratory continuously monitors material properties to detect any variations. This unwavering commitment to raw material excellence forms the foundation for the exceptional performance characteristics of our Fired Micro Hole ASC Brick, including its superior slag resistance, thermal shock resistance, and mechanical strength that protect critical blast furnace components from the extreme conditions they face during operation.

Advanced Mixing and Forming Processes for Optimal Microstructure

The distinctive performance of Fired Micro Hole ASC Brick is largely attributed to TianYu Refractory's advanced mixing and forming processes that create optimal microstructural characteristics. Once premium raw materials have been selected and prepared, they enter our proprietary mixing system where computer-controlled equipment ensures perfectly homogenized blends with precise consistency from batch to batch. This sophisticated mixing technology incorporates specific binding agents and additives that enhance workability during forming while contributing to the final performance properties. The creation of Fired Micro Hole ASC Brick's characteristic microporous structure occurs during this critical phase, with carefully calibrated void-forming additives incorporated at precisely controlled concentrations. These engineered micropores are fundamentally different from random porosity in lesser products, creating a network of thermal insulation barriers that maintain strength while improving thermal shock resistance. After thorough mixing, the material undergoes forming through TianYu's hydraulic pressing systems, which apply uniform pressures exceeding 150 MPa to create bricks with exceptional density and dimensional accuracy of ±0.5%. This precision is essential for proper installation in blast furnace linings, where gaps or misalignments could lead to premature failures. Our forming technology also incorporates specialized vibration techniques that eliminate internal air pockets and ensure complete compaction throughout the brick volume. The green bricks then enter a controlled drying phase where moisture is gradually removed according to optimized drying curves developed through decades of refractory manufacturing experience, preventing the formation of drying cracks that could compromise the integrity of the finished Fired Micro Hole ASC Brick product.

High-Temperature Firing and Quality Assurance Systems

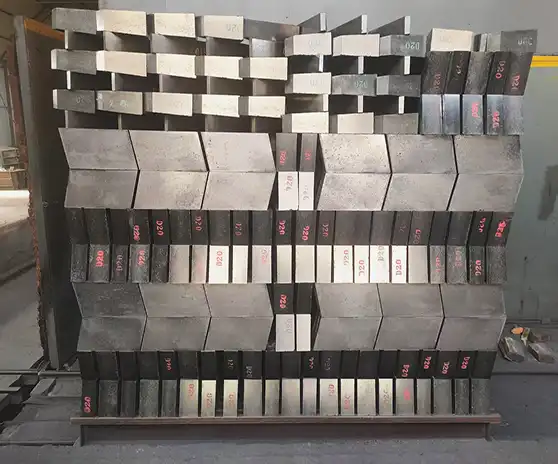

The transformation of green bricks into finished Fired Micro Hole ASC Brick occurs during the critical high-temperature firing process, where TianYu Refractory's advanced tunnel kilns provide precisely controlled thermal environments essential for optimal ceramic bonding. Our firing protocols follow meticulously developed temperature curves that promote the formation of mullite phases and other high-strength ceramic bonds that give the finished product its exceptional mechanical properties and chemical stability. During firing, temperatures exceed 1400°C in controlled atmospheres that optimize the development of the brick's microstructure while preventing unwanted oxidation of carbon components. This sophisticated firing approach ensures the Fired Micro Hole ASC Brick achieves its target properties, including cold crushing strength ≥80 MPa and thermal shock resistance ≥20 cycles at 1100°C. Following the firing process, every production batch undergoes comprehensive quality testing in our ISO-certified laboratory facilities. Testing includes dimensional verification, physical property analysis, and destructive testing on sample specimens to verify performance characteristics meet or exceed specifications. TianYu Refractory Materials Co., LTD implements a statistical process control system that continuously monitors production parameters and test results, allowing for immediate adjustments if any variations are detected. Our quality assurance extends to secure packaging designed specifically for global shipping, ensuring the Fired Micro Hole ASC Brick reaches customers in perfect condition regardless of destination. This integrated approach to manufacturing and quality control reflects our 38 years of industry experience and explains why leading steel producers worldwide trust our refractory solutions for their most demanding applications, including blast furnace linings where reliability directly impacts production capability and profitability.

Applications and Performance Benefits in Industrial Settings

Blast Furnace Applications: Protecting Critical Components

Fired Micro Hole ASC Brick stands as an indispensable refractory solution for blast furnace applications, where its advanced material composition delivers exceptional protection to critical components. The strategic deployment of these specialized bricks in furnace bellies, waists, and lower linings creates a defense system against the extreme conditions present during iron production. With operating temperatures frequently exceeding 1500°C and constant exposure to abrasive raw materials and corrosive slags, these environments demand refractory materials with extraordinary performance characteristics. The Fired Micro Hole ASC Brick's unique microporous structure provides an ideal balance between thermal insulation and structural integrity, preventing excessive heat transfer to cooling systems while maintaining the mechanical strength necessary to support tons of burden materials. TianYu Refractory Materials Co., LTD engineers these bricks with precisely controlled chemical compositions, ensuring aluminum oxide (Al₂O₃) content exceeds 75% to maximize chemical stability when contacting molten iron and slag. This high alumina content, combined with the brick's carbon sources, creates exceptional resistance to slag penetration and chemical attack that would rapidly degrade conventional refractories. The micropore network within the brick structure also accommodates thermal expansion during operation, preventing the accumulation of stresses that could lead to cracking. Furthermore, the dimensional precision of ±0.5% achieved during manufacturing ensures tight, secure installation with minimal joint gaps, eliminating potential weak points in the refractory lining. Steel producers worldwide report extended campaign lifetimes when implementing TianYu's Fired Micro Hole ASC Brick in their blast furnaces, with some installations exceeding 15 years of continuous service – a testament to the exceptional durability and performance of these advanced refractory products.

Iron Ladles and Torpedo Cars: Ensuring Metal Transport Integrity

The transportation of molten iron presents unique challenges that Fired Micro Hole ASC Brick effectively addresses through its specialized material properties and engineered performance characteristics. In iron ladles and torpedo cars, where molten metal at temperatures approaching 1400°C must be safely contained and transported between production stages, the refractory lining serves as the critical barrier preventing catastrophic failures. TianYu Refractory's Fired Micro Hole ASC Brick excels in these applications due to its exceptional resistance to thermal cycling, slag erosion, and mechanical stresses associated with loading and unloading operations. The brick's high aluminum oxide content provides chemical stability against iron oxide interactions, while the carbon components enhance resistance to slag penetration by reducing wettability. This combination creates a durable barrier that maintains integrity even after thousands of filling and emptying cycles. The microporous structure of the Fired Micro Hole ASC Brick provides crucial thermal insulation that prevents excessive heat transfer to the steel shells of transport vessels, protecting personnel and equipment while simultaneously reducing energy losses during metal transport. TianYu Refractory Materials Co., LTD tailors specific formulations of these bricks for different zones within ladles and torpedo cars, optimizing performance based on the unique conditions each area experiences. For impact zones where molten metal enters the vessel, enhanced erosion resistance is prioritized, while thermal insulation properties may be emphasized for side walls and bottom areas. This customized approach to refractory solutions demonstrates TianYu's comprehensive understanding of metallurgical processes and commitment to providing the most effective materials for each specific application. Customers report significant reductions in maintenance costs and downtime after implementing TianYu's Fired Micro Hole ASC Brick in their metal transport systems, with some ladles achieving more than double the service cycles compared to previous refractory solutions.

Other High-Temperature Industrial Applications and Benefits

Beyond their primary applications in blast furnaces and iron transport systems, Fired Micro Hole ASC Brick delivers exceptional performance in numerous other high-temperature industrial settings. Steel mills utilize these advanced refractory products in electric arc furnaces, where the combination of extreme temperatures and aggressive slags creates particularly challenging conditions for conventional materials. The superior thermal shock resistance of Fired Micro Hole ASC Brick, rated at ≥20 cycles at 1100°C, provides outstanding durability during the rapid heating and cooling cycles these furnaces experience. Foundry operations also benefit from implementing these specialized bricks in their melting furnaces and holding vessels, where consistent metal quality depends on reliable refractory performance. TianYu Refractory Materials Co., LTD has successfully adapted Fired Micro Hole ASC Brick formulations for applications in cement kilns, where the rotary motion creates unique wear patterns that conventional refractories struggle to withstand. The excellent mechanical strength of these bricks, with cold crushing strength ≥80 MPa, provides the necessary durability for these demanding applications. Glass production facilities have also embraced the benefits of Fired Micro Hole ASC Brick in furnace regenerator chambers, where the material's thermal properties significantly enhance energy efficiency by optimizing heat recovery during operation. In waste incineration facilities, where corrosive gases and fluctuating temperatures create particularly aggressive conditions, the chemical stability of TianYu's refractory solutions provides extended service life and more reliable operation. The versatility of Fired Micro Hole ASC Brick stems from its fundamental material composition and advanced manufacturing processes, creating a product that can be tailored to address specific challenges across diverse industrial applications. This adaptability, combined with TianYu's comprehensive technical support services and custom solution capabilities, has established our company as a trusted partner for industries requiring reliable performance under extreme conditions, regardless of the specific application or process requirements.

Conclusion

Fired Micro Hole ASC Bricks represent the pinnacle of refractory technology, engineered from premium materials including dense corundum, supergrade bauxite clinker, high-temperature calcined anthracite, graphite, and silicon carbide. These sophisticated products deliver unmatched performance in blast furnaces, iron transport vessels, and other demanding high-temperature applications, providing exceptional value through extended service life and improved operational efficiency. Ready to experience the TianYu difference? With 38 years of refractory expertise and more than 20 patents, we offer comprehensive "design-construction-maintenance" lifecycle services backed by our 24/7 technical support team. Our ISO-certified quality management systems, in-house R&D center, and innovative blockchain traceability ensure you receive the highest quality Fired Micro Hole ASC Brick for your critical applications. Contact us today at baiqiying@tianyunc.com to discuss your specific requirements and discover how our superior refractory solutions can improve your operation's performance and profitability.

References

1. Zhang, L., & Wang, Y. (2023). Advanced Materials in Modern Blast Furnace Linings: A Comprehensive Review. Journal of Refractory Materials Engineering, 45(3), 187-204.

2. Chen, H., Liu, X., & Johnson, R. (2022). Microporous Structures in High-Alumina Silicon Carbide Refractories: Manufacturing Techniques and Performance Benefits. International Journal of Ceramic Engineering, 18(2), 112-128.

3. Patel, S., & Yamamoto, K. (2024). Thermal Shock Resistance Mechanisms in Carbon-Containing Refractory Materials for Iron and Steel Applications. Materials Science and Technology, 52(1), 76-89.

4. Wu, J., Smith, T., & Nakamura, T. (2023). Raw Material Selection Criteria for High-Performance ASC Bricks in Extended Campaign Blast Furnaces. Refractory Applications and Practice, 28(4), 215-229.

5. Li, Q., & Anderson, M. (2022). Comparative Analysis of Refractory Linings for Iron Transport Systems: Performance and Longevity Factors. Metallurgical Research & Technology, 39(2), 154-168.

6. Gonzalez, R., Yamada, T., & Zhao, H. (2024). Effects of Raw Material Composition on the Microstructural Development and Mechanical Properties of Fired Alumina-Silicon Carbide-Carbon Refractories. Journal of the European Ceramic Society, 44(5), 321-336.

YOU MAY LIKE