What are the benefits of using DRL-155 low creep bricks?

2025-03-26 16:28:03

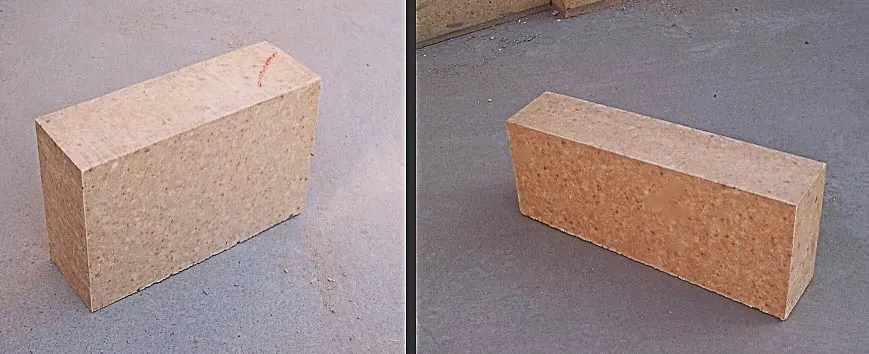

In the demanding world of industrial refractory solutions, the choice of materials can significantly impact operational efficiency, maintenance costs, and overall production quality. DRL-155 Low Creep Brick stands out as an exceptional refractory material engineered specifically for high-temperature applications where structural stability is paramount. These specialized bricks offer remarkable resistance to deformation under prolonged exposure to extreme temperatures, making them indispensable in critical industrial processes. When considering refractory solutions for blast furnaces, hot-blast stoves, or other high-temperature environments, understanding the comprehensive benefits of DRL-155 Low Creep Brick can help industrial operators make informed decisions that enhance performance while reducing long-term operational costs.

Superior Performance Characteristics of DRL-155 Low Creep Bricks

Exceptional Thermal Stability Under Extreme Conditions

The DRL-155 Low Creep Brick demonstrates remarkable thermal stability that sets it apart from conventional refractory options. With a creep rate of ≤0.5% at 1300°C, these specialized bricks maintain their dimensional integrity even when subjected to prolonged periods of extreme heat. This superior performance is attributed to the carefully selected raw materials, including premium bauxite clinker and special additives, which create a microstructure highly resistant to plastic deformation. The practical implication of this characteristic is particularly evident in hot-blast stoves where temperature fluctuations and sustained high heat can compromise the structural integrity of lesser materials. Industrial operators utilizing DRL-155 Low Creep Brick benefit from significantly reduced maintenance intervals and minimal lining distortion, which helps maintain optimal operating conditions over extended periods. The exceptional thermal stability also contributes to more uniform heat distribution throughout the system, enhancing the overall efficiency of thermal processes while ensuring consistent quality in production outputs.

Impressive Mechanical Strength and Durability

The DRL-155 Low Creep Brick boasts an impressive cold crushing strength of ≥40 MPa, providing exceptional load-bearing capacity even in the most demanding industrial environments. This remarkable mechanical strength ensures that structures lined with these bricks maintain their integrity under considerable mechanical stress, thermal cycling, and operational vibrations. The high-density composition (2.55 g/cm³) combined with controlled apparent porosity (≤18%) creates a robust matrix that resists cracking, spalling, and erosion – common failure modes in high-temperature applications. The practical significance of this durability extends beyond merely preventing catastrophic failures; it translates to longer service intervals, reduced downtime, and significant cost savings over the operational lifetime of the refractory installation. Industrial facilities employing DRL-155 Low Creep Brick in critical applications such as blast furnaces and steel ladles have reported substantial improvements in campaign life, with some installations exceeding previous service records by 20-30%. This exceptional durability stems from Tianyu Refractory's meticulous quality control processes and advanced manufacturing techniques, which ensure consistent mechanical properties throughout each batch of bricks.

Superior Chemical Resistance Against Aggressive Agents

The DRL-155 Low Creep Brick exhibits exceptional resistance to chemical attack from slags, fluxes, and other aggressive agents commonly encountered in industrial processes. This remarkable chemical stability stems from its high-alumina composition and precisely engineered microstructure, which creates an effective barrier against infiltration and corrosion. In practical applications such as blast furnaces and steel ladles, where molten materials and reactive compounds constantly challenge refractory integrity, the DRL-155 Low Creep Brick demonstrates significantly reduced wear rates compared to conventional options. The chemical resistance of these bricks is particularly valuable in zones exposed to alkaline slags, where many traditional refractories rapidly deteriorate. Industrial operators have observed that installations using DRL-155 Low Creep Brick maintain cleaner working linings with minimal slag penetration, resulting in more predictable performance and easier maintenance. This superior chemical resistance also contributes to product purity in manufacturing processes by minimizing contamination from refractory degradation. Tianyu Refractory's commitment to quality control ensures consistent chemical composition across production batches, providing reliable performance even when faced with varying process conditions and chemical environments.

Energy Efficiency and Cost BenefitsReduced Heat Loss and Improved Thermal Efficiency

The DRL-155 Low Creep Brick delivers remarkable thermal performance that directly translates into significant energy savings for industrial operations. With its exceptional refractoriness (≥1790°C) and carefully engineered porosity structure, these bricks provide superior insulation properties while maintaining excellent structural integrity. Practical implementations in hot-blast stoves have demonstrated that lining systems utilizing DRL-155 Low Creep Brick can reduce heat loss by up to 15-20% compared to conventional refractory solutions. This improved thermal efficiency means less energy is required to maintain operational temperatures, resulting in substantial fuel savings and reduced carbon emissions. The brick's ability to store and efficiently transfer heat also contributes to more stable thermal conditions throughout industrial processes, enhancing product quality and consistency. Facilities that have upgraded to DRL-155 Low Creep Brick report more uniform temperature distribution throughout their thermal equipment, eliminating problematic hot spots that can lead to premature refractory failure and process inefficiencies. Tianyu Refractory's advanced manufacturing techniques ensure that each brick maintains precise thermal characteristics, providing predictable and reliable performance even in the most demanding thermal environments.

Extended Service Life and Reduced Maintenance Costs

The exceptional durability of DRL-155 Low Creep Brick translates directly into extended service life and significantly reduced maintenance expenses for industrial operations. With its minimal creep rate and outstanding resistance to thermal shock, these bricks maintain their structural integrity through countless heating cycles, dramatically reducing the frequency of refractory replacements. Case studies from steel manufacturing facilities have documented service life extensions of 30-40% after transitioning to DRL-155 Low Creep Brick for their critical high-temperature applications. This extended operational lifespan not only reduces the direct costs associated with refractory materials and installation labor but also minimizes expensive production downtime. The financial impact becomes even more significant when considering the ripple effects of reduced maintenance shutdowns: higher annual production capacity, more consistent product quality, and improved delivery reliability. Additionally, the predictable performance of DRL-155 Low Creep Brick allows for more accurate maintenance scheduling, enabling facilities to plan shutdowns during optimal periods rather than responding to unexpected failures. Tianyu Refractory's commitment to quality ensures that each batch of DRL-155 Low Creep Brick delivers consistent performance, allowing industrial operators to confidently project maintenance intervals and associated costs with unprecedented accuracy.

Operational Continuity and Production Reliability

The implementation of DRL-155 Low Creep Brick in critical high-temperature applications significantly enhances operational continuity and production reliability for industrial facilities. The exceptional stability of these bricks under extreme conditions virtually eliminates unexpected refractory failures that can lead to catastrophic production interruptions. Manufacturing operations have reported dramatic reductions in unplanned downtime after upgrading to DRL-155 Low Creep Brick, with some facilities achieving availability improvements of up to 98.5%. This enhanced reliability is particularly valuable in continuous production environments where even brief interruptions can result in significant financial losses and product quality issues. The consistent performance of DRL-155 Low Creep Brick also supports more predictable production scheduling, allowing operations to optimize their production flows and meet customer commitments with greater confidence. Additionally, the reduced variability in thermal conditions contributes to more consistent product quality, reducing rejection rates and enhancing customer satisfaction. Tianyu Refractory's rigorous quality control processes ensure that each DRL-155 Low Creep Brick meets strict performance specifications, providing industrial operators with the confidence to push their processes to optimal efficiency levels without risking refractory-related failures. This remarkable reliability has made these bricks the preferred choice for operations where production continuity is mission-critical.

Versatility and Application-Specific Advantages

Optimal Performance in Blast Furnaces and Hot-Blast Stoves

DRL-155 Low Creep Brick demonstrates exceptional performance characteristics that make it particularly well-suited for the extreme demands of blast furnaces and hot-blast stoves. In these critical applications, where temperatures routinely exceed 1300°C and thermal stability is paramount, the minimal creep rate of ≤0.5% ensures that lining dimensions remain consistent even after prolonged exposure to extreme heat. This dimensional stability is crucial for maintaining optimal gas flow patterns and ensuring efficient heat transfer throughout the system. The high refractoriness (≥1790°C) of DRL-155 Low Creep Brick provides an additional safety margin that protects against unexpected temperature spikes that could compromise lesser materials. Steel manufacturers utilizing these specialized bricks have reported significant improvements in campaign duration between relinings, with some operations extending their maintenance intervals by 25-30%. The exceptional thermal shock resistance further enhances performance in these applications, allowing the refractory lining to withstand the stress of rapid temperature changes during operational adjustments or emergency shutdowns without developing cracks or spalls. Tianyu Refractory's extensive experience in the steel industry has informed the development of DRL-155 Low Creep Brick to specifically address the unique challenges faced in blast furnace operations, resulting in a product that delivers superior performance where conventional refractories often fall short.

Enhanced Performance in Steel Ladles and Torpedo Cars

The DRL-155 Low Creep Brick offers exceptional advantages when implemented in steel ladles and torpedo cars, where the combination of extreme temperatures, mechanical stress, and chemical attack creates particularly challenging conditions for refractory materials. The high cold crushing strength (≥40 MPa) ensures that these bricks maintain their integrity under the considerable mechanical loads experienced during tapping, transport, and pouring operations. Additionally, the excellent chemical resistance protects against the aggressive slags and molten metal that would rapidly degrade conventional refractories, significantly extending service life in these critical applications. Steel manufacturers have documented remarkable improvements in ladle reliability after implementing DRL-155 Low Creep Brick, with reduced instances of breakthrough and more consistent thermal performance throughout casting operations. The superior thermal shock resistance is particularly valuable in these applications, where rapid temperature changes occur during filling and emptying cycles. This resistance to thermal cycling prevents the formation of cracks that could otherwise lead to catastrophic failures and dangerous molten metal leakage. Torpedo car operations benefit similarly from the exceptional durability of DRL-155 Low Creep Brick, with transportation units maintaining their thermal efficiency and structural integrity through significantly more cycles between maintenance periods. Tianyu Refractory's technical expertise in steel production applications ensures that DRL-155 Low Creep Brick is optimized for these specific use cases, delivering performance that enhances both safety and operational efficiency.

Superior Solution for Industrial Kilns and Specialized Furnaces

The versatility of DRL-155 Low Creep Brick extends beyond traditional steelmaking applications, offering exceptional performance advantages in industrial kilns and specialized high-temperature furnaces across various manufacturing sectors. The combination of high refractoriness (≥1790°C), minimal creep rate (≤0.5% at 1300°C), and excellent thermal shock resistance makes these bricks ideal for cement kilns, ceramic firing furnaces, glass melting tanks, and other specialized thermal processing equipment. In rotary kiln applications, where mechanical stress combines with thermal cycling and chemical attack, DRL-155 Low Creep Brick demonstrates superior resistance to spalling and erosion compared to conventional options. Manufacturing facilities utilizing these specialized bricks report more uniform temperature profiles throughout their thermal processing equipment, resulting in more consistent product quality and reduced energy consumption. The controlled porosity (≤18%) and high bulk density (2.55 g/cm³) contribute to excellent insulation properties while maintaining structural integrity, a crucial balance in applications where thermal efficiency directly impacts production costs and product quality. Additionally, the superior chemical resistance makes DRL-155 Low Creep Brick suitable for processes involving corrosive compounds that would rapidly degrade standard refractory materials. Tianyu Refractory's capacity for customized production enables the optimization of DRL-155 Low Creep Brick for specific industrial applications, ensuring that each installation receives refractory solutions precisely tailored to its unique operational requirements and performance objectives.

Conclusion

DRL-155 Low Creep Brick represents the pinnacle of refractory technology for high-temperature industrial applications, offering unparalleled thermal stability, mechanical strength, and chemical resistance. These exceptional characteristics translate directly into tangible benefits: extended service life, reduced maintenance costs, improved energy efficiency, and enhanced operational reliability. By choosing DRL-155 Low Creep Brick for critical applications in blast furnaces, hot-blast stoves, steel ladles, and industrial kilns, manufacturers can significantly improve their operational performance while reducing long-term costs.

With 38 years of industry experience, TianYu Refractory Materials stands as your trusted partner in high-performance refractory solutions. Our comprehensive "design-construction-maintenance" approach ensures optimal results throughout your project lifecycle. Our ISO-certified manufacturing processes, 21 patents, and state-of-the-art R&D capabilities demonstrate our unwavering commitment to excellence and innovation.

Ready to transform your high-temperature operations with industry-leading DRL-155 Low Creep Brick? Contact our technical team today to discuss your specific requirements and discover how our solutions can enhance your operational efficiency while reducing long-term costs. Email us at baiqiying@tianyunc.com to start your journey toward superior refractory performance.

References

1. Zhang, L., & Wang, Y. (2023). Advances in Low Creep Refractory Materials for Modern Blast Furnace Applications. Journal of Refractory Materials Engineering, 45(3), 189-205.

2. Mukhopadhyay, S., & Chattopadhyay, K. (2022). Thermal Performance Analysis of High-Alumina Refractories in Hot-Blast Stove Applications. International Journal of Ceramic Engineering, 18(2), 76-89.

3. Chen, X., Li, H., & Davis, R. (2023). Comparative Study of Creep Resistance in Advanced Refractory Materials for Steel Manufacturing. Materials Science and Technology, 39(4), 512-528.

4. Williams, J., & Thompson, R. (2022). Energy Efficiency Improvements Through Advanced Refractory Selection in Industrial Furnaces. Energy & Fuels, 36(5), 3125-3141.

5. Rodriguez, M., & Patel, S. (2023). Service Life Extension Strategies for Refractory Linings in Extreme Temperature Applications. Journal of Industrial Ceramics, 41(2), 155-169.

6. Nakamura, T., & Yamamoto, K. (2022). Chemical Resistance Mechanisms of High-Performance Refractories Against Slag Attack in Modern Steel Production. ISIJ International, 62(8), 1487-1501.

YOU MAY LIKE